Features

- To reduce microbiological load; and increase life span of material.

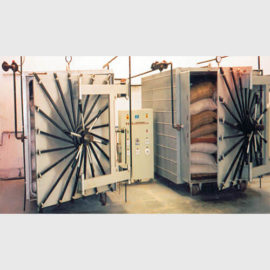

- Modular construction of chamber.

- Door locking vacuum and pressure seal.

- Easy to operate.

- Fully Automatic / Manual operation version.

- Heating facility ( Electrical / Diesel / Kerosene / Gas ) incorporated.

- Steam generation and injection system.

- 90 % /10 % Ethylene can be used in a same machine.

- Material loading trolley with truck ( optional).

- Water ring type vacuum pump.

- Residual discharge gas will form Ethylene glycol liquid.

- Electric control panel with Audio – visual signals.

- Standard Size of Chamber :

- 2 x 2 x 4 met. 1 x 1 x 2 met.

- 1.55 x 1.5 x 3 met. 0.5 x 0.5 x 1 met sizes.

- 1.22 x 1.22 x 2.5 met. Process time about 8 hrs.

It is useful prevention of micro biological contamination retairing flavour useful for treatment of spices; dried nuts; Foods Packed cereals etc..